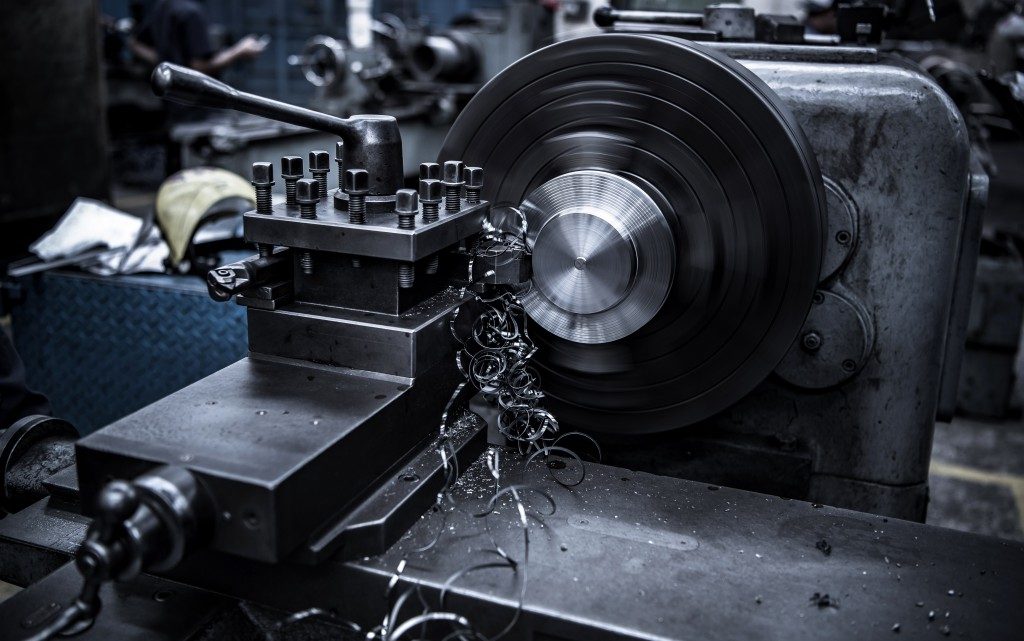

The development of sophisticated techniques has been a constant element since the Industrial Revolution. Nowadays, technologies are primarily focused on the automation of industrial operations. Industrial automation denotes a process through which industrial equipment requires reduced human intervention for their decision-making. The process is designed to increase your production, reduce your operating expenses, guarantee efficient use of your raw materials, and reduce your industry’s energy consumption.

The automation of processes in an industry is not as easy as including a few controls. You need an automated control company based in Utah to assess your needs and recommend what will work best for you. Various automation levels might suffice for your business.

Field Level

This marks the lowest industry automation level and comprises the use of field devices like actuators and sensors. The sensors will collect data on speed, temperature, pressure, and other elements then convert them into electrical signals before relaying them to another level. The actuators include devices like switches, valves, and motors that translate signals into actions. The primary task of field level automation is the transfer of data on industrial processes to machines for analysis and monitoring.

Control Level

This is a mid-level automation hierarchy where all automation related programs will be executed. In the control level, therefore, PLCs and controllers that generate real-time computing are used. PLCs are generally implemented using 32 or 16-bit microcontrollers that will run on proprietary operating systems to meet real-time requirements. The PLCs can also be interfaced with multiple I/O devices and thus communicate using various communication protocols such as CAN. This allows technicians to program different control strategies or functions that handle particular automation operations.

Supervisory Level

Here, monitoring systems and automation devices will facilitate the adjustment and control functions of your industry. These include human-machine interfaces, supervisory control and data acquisition, and distribution control systems. They are used for setting various production targets and machine shutdown and starts, historical archiving, and monitoring different parameters. The supervisory level automation comprises an industrial PC often available as a rack-mounted, desktop, or panel PC on which a specific software runs. This software mainly handles process parameterization and visualization.

Enterprise Level

This marks the highest industry automation level. It is sometimes known as information-level automation and manages your entire automation system. This level handles your production planning, market and customer analysis, and sales and orders. As such, the enterprise automation level will focus more on the commercial aspects of your industry rather than the technical aspects.

In the end, remember that there are three types of industrial automation: fixed, flexible, and integrated automation systems. In fixed automation, the tasks and operations in your industry will not change, while in programmable automation, the configuration of machines is changed using electronic controls. Flexible automation is implemented and controlled using computers, while integrated automation encompasses independent processes, data, and devices. If you want to boost the safety and profits in your industry, get an expert to determine which of the levels of automation work for you.