The global industrial automation market is expected to grow at a CAGR of 9.8% from 2022 until it reaches $395.09 billion in 2029. This expected growth can be attributed to the increasing demand for industrial automation due to the growing need for efficiency and productivity in manufacturing. The industry is always changing and evolving. New technologies are constantly being developed to help increase productivity, efficiency, and safety in the workplace. As such, here are some automation tech trends that are expected to impact manufacturing:

Safety Tech for Workers

There has been an increasing focus on safety in the manufacturing industry. This is due in part to the recognition of the potential hazards associated with factory work, as well as the introduction of new technologies that can help to improve safety. One example of such technology is the exoskeleton, which is a wearable device that can assist with lifting and other physically demanding tasks.

Other safety tech includes smart helmets, equipped with sensors that can monitor workers’ vital signs and provide early warning signs of fatigue or illness. These helmets can also be equipped with GPS tracking, which can be used to locate workers in an emergency. By investing in safety tech, factories can create a safer environment for their workers and help to reduce the number of accidents and injuries.

Automating Machinery

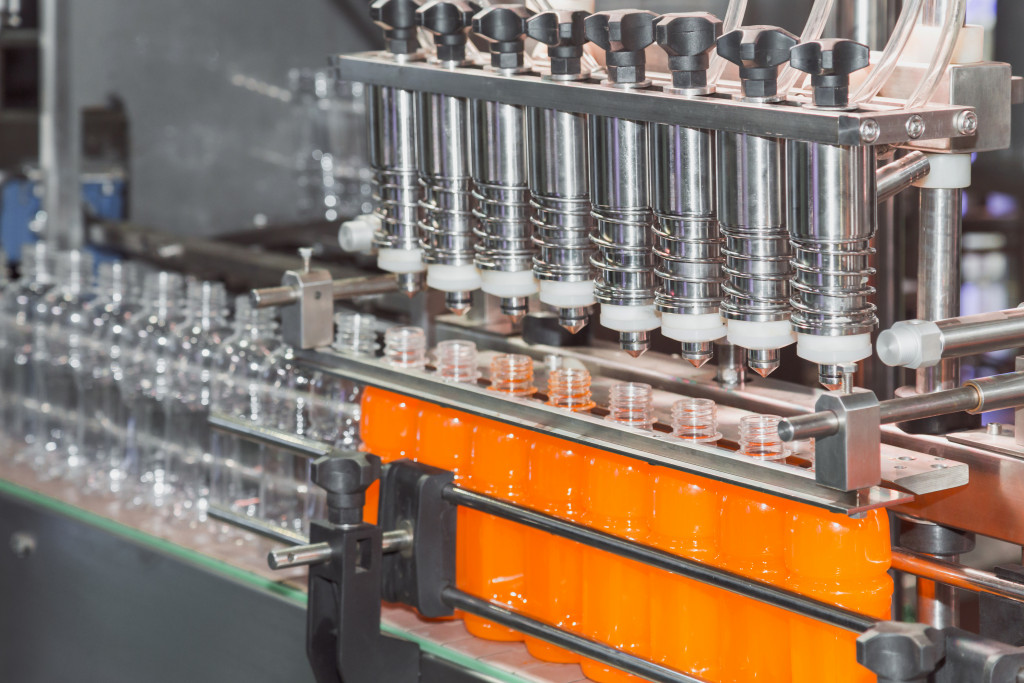

Another big trend that’s expected to make a more significant impact in manufacturing is machinery automation. This is already being used in many factories, and it will only become more advanced and widespread in the years to come. The benefits of using automated machinery include increased productivity, decreased costs, and improved product quality.

Moreover, using pneumatic systems in automation is becoming increasingly common as technology advances. These systems use air to do things like move things around or make them work. It uses cylinders, valves, and sensors to control motion. Each with its own function. So if any of these parts break, replacing them is essential. For instance, valves are used to control airflow direction. If it needs replacement, your entire system might be affected. That’s why getting new pneumatic valves can ensure that your entire system will continue to function smoothly and avoid downtime.

Collaborative Robots

Collaborative robots, or “cobots,” are designed to work alongside humans, and they’re often used for tasks like quality control or assembly line work. One of the advantages of using cobots is that they can help reduce errors and increase productivity. For example, suppose a human worker is trying to assemble a product. In that case, a cobot can be used to handle some smaller tasks, such as attaching screws or adding components. This frees up the human worker to do other tasks and helps to improve the overall efficiency of the assembly process. In addition, cobots can be programmed to work around the clock, which means they can help to increase production levels without sacrificing quality.

The Internet of Things (IoT)

IoT-enabled devices can provide real-time data about things like equipment performance or material levels, which can help businesses make better decisions about production planning and quality control. In addition, IoT-based systems can automate various manufacturing processes, from machine operation to product assembly. This can lead to increased efficiency and productivity, as well as reduced costs. As more and more manufacturers adopt IoT technology, the competitive landscape will likely change and offer more growth opportunities for many businesses.

Warehouse Drones

Drones are becoming increasingly popular in the manufacturing industry, as they offer many advantages over traditional methods. For example, drones can be used for inventory management or product delivery tasks, providing more data accuracy and work efficiency. If workers need to search for a specific item, they can use drones to find and retrieve it in a warehouse.

In addition, drones are much less likely to damage products or injure themselves, which makes them ideal for use in delicate or dangerous environments. However, there are some disadvantages to using drones in manufacturing, such as the high purchase and maintenance cost and the risk of data breaches if the drones are not properly secured. Nevertheless, with the right security measures, drones can help businesses to streamline their processes and improve their overall efficiency.

These are just some top automation tech trends that are expected to impact manufacturing in the next few years. There’s a lot of exciting new technology on the horizon that has the potential to revolutionize the way the industry manufactures products. So if you’re involved in the manufacturing industry, make sure you stay up-to-date on all the latest trends so you can be ready for what’s ahead.